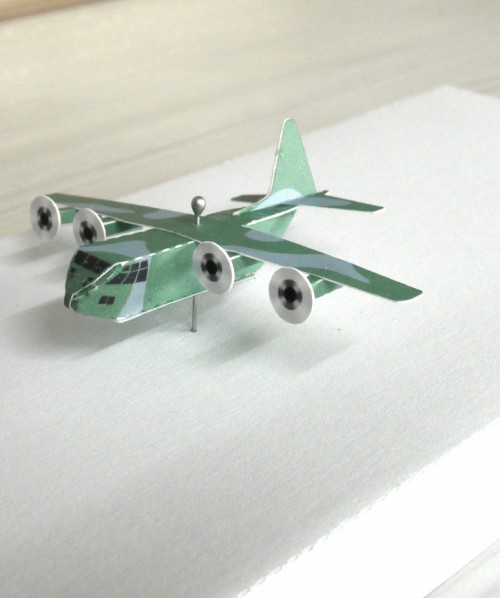

This was an experiment: I wanted to see how well Shapeway’s stainless steel prints turn out, especially for tiny details. For a test, I picked a model of the Lockheed Model 10 Electra – the airplane Amelia Earheart flew on her last flight.

I will be showing some paper airplane models at the Aero Expo starting on Wednesday, April 14, and I thought it would be nice to bring along a 3D printed steel model as well.

I had made a paper model of a similar Lockheed airplane before, and after tinkering with the schematics a little bit (more on this in a future tutorial), I had a 3D model that was fit for printing.

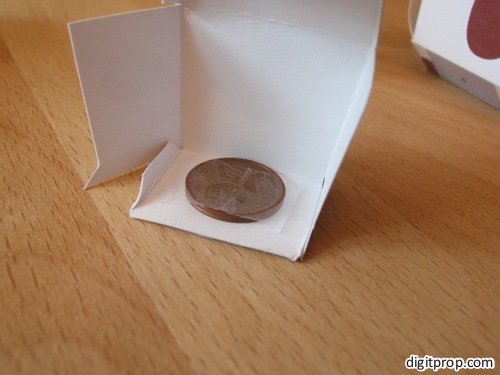

Turns out, Shapeway managed to produce a very nice print. This is not plastic, but stainless steel. It’s bronze-infused, meaning it has an almost golden sheen to it.

As far as I know, Shapeways uses a sintering process to print these, so there is no need for support material, and thus no visible attachment points. Being used to working with plastics, the weight of a stainless steel model feels great, too.

The details turned out very nice. I was concerned with the propeller blades, as they are very small and thin, but they printed nicely and don’t feel like they will break off easily.

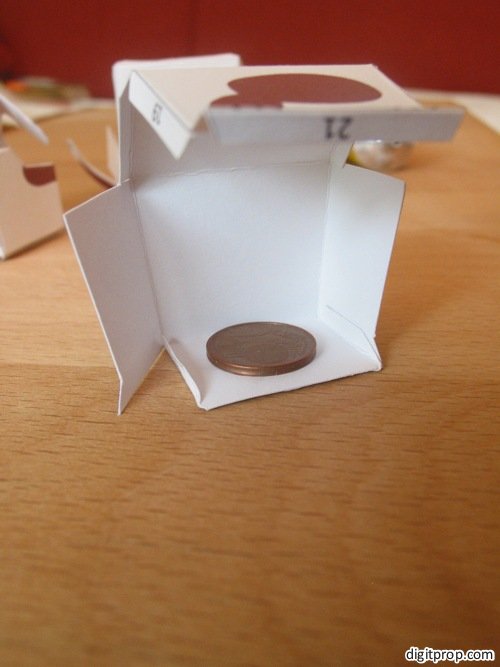

So, all in all I would consider this a success, except maybe for the price, which is not horrible, but not insignificant either – after all, this is a very small model (about 5cm long). Nevertheless, if you want to have one, too, you can order it from Shapeways. Mine took about one week for printing and shipping.